Key Takeaways

- Flexible LED PCB flex circuits utilize specialized materials—like polyimide films, copper foils, advanced adhesives, and protective solder masks—to achieve high flexibility, durability, and electrical performance.

- Polyimide acts as the primary substrate, providing exceptional heat resistance (up to 200°C) and mechanical stability, making it ideal for demanding electronic applications.

- Rolled-annealed copper foils ensure reliable conductivity and resist cracking during repeated bending, while surface finishes like ENIG prevent oxidation.

- Adhesive systems, including acrylics and epoxies, maintain strong bonding between layers without compromising flexibility or thermal endurance.

- Solder masks and overlay films protect the circuits from moisture, abrasion, and electrical shorts, significantly extending product lifespan.

- Flexible LED PCB flex circuits are widely used in automotive lighting, wearable electronics, architectural displays, and medical devices—enabling reliable performance in tight, bendable, or uniquely shaped spaces.

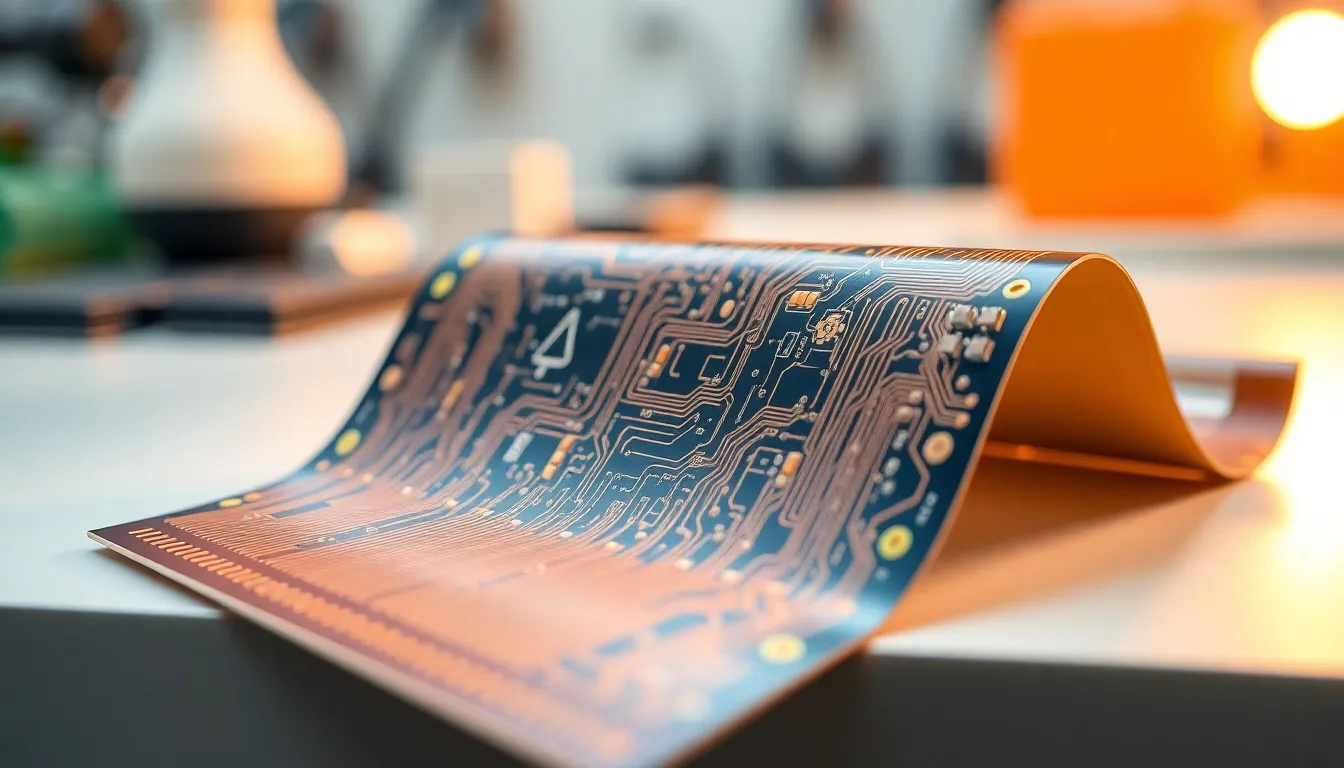

Flexible LED PCB flex circuits utilise specialised materials including polyimide films, copper foils, advanced adhesives, and protective solder masks to achieve exceptional flexibility whilst maintaining electrical performance. Polyimide substrates provide heat resistance up to 200°C and mechanical stability, whilst rolled-annealed copper foils ensure reliable conductivity during repeated bending. These circuits enable innovative designs in automotive lighting, wearable electronics, and architectural displays where traditional rigid boards cannot function. Manufacturers like WellPCB produce these flexible circuits for applications requiring reliable performance in tight or uniquely shaped spaces.

Overview of Flexible LED PCB Flex Circuits

Flexible LED PCB flex circuits use thin layers to enable bending and forming into non-flat surfaces without loss of electrical function. Polyimide films serve as the primary base material, providing stability under mechanical stress up to 200°C, as proven by IPC-4101 standards. Copper foils form the conductive traces, typically in thicknesses like 18μm or 35μm, ensuring efficient current flow in LED applications. Adhesive systems, such as acrylic or epoxy, bond conductive and insulator layers while supporting flexibility and thermal resistance. Solder masks and protective overlays, including polyimide or liquid photoimageable coverings, shield circuits from moisture and mechanical abrasion.

WellPCB in China manufactures flexible LED PCB flex circuits for use in backlight assemblies, wearable lighting, and compact display modules. Their processes combine precision etching and automated inspection for consistent conductor alignment and assembly quality. This ensures reliability in flexible circuit performance during continuous flexing and in spatially constrained product housings.

Key Materials Used in Flexible LED PCB Flex Circuits

Flexible LED PCB flex circuits rely on a well-defined combination of engineered materials to achieve durability, reliability, and flexibility. Materials selection directly impacts the circuit’s thermal, mechanical, and electrical performance, influencing suitability for advanced lighting and wearable electronics.

Polyimide as the Base Substrate

Polyimide films support flexible LED PCB flex circuits as a base substrate, sustaining repeated bending and consistent function. Polyimide withstands continuous temperatures up to 200°C and resists chemicals, supporting stable functionality in automotive backlights, medical wearables, and consumer electronics. WellPCB sources certified polyimide laminates that comply with IPC-4101 standards, ensuring robust electrical insulation and dimensional stability during precision etching and automated inspection.

Conductive Copper Foils

Copper foils provide electrical pathways in flexible LED PCB flex circuits through precisely etched trace patterns. Rolled-annealed copper resists work hardening and cracking under flexing, maintaining conductivity in high-density assemblies and dynamic displays. WellPCB applies copper layers at thicknesses between 12µm and 70µm, enabling designers to balance flexibility, current-carrying capability, and miniaturization. Specialized surface finishes, such as ENIG or OSP, prevent oxidation and support long-term performance.

Adhesives and Bonding Agents

Adhesives and bonding agents secure the layers in flexible LED PCB flex circuits without sacrificing flexibility or thermal endurance. Acrylic-based or epoxy adhesives withstand soldering temperatures up to 260°C, supporting multi-layer stackups and component attachment while minimizing delamination risk. WellPCB engineers customize adhesive selection for moisture and heat resistance, optimizing production runs for ambient, automotive, and industrial operating conditions.

Protective Solder Masks and Overlays

Solder masks and overlay films protect flexible LED PCB flex circuits from moisture, oxidation, and accidental shorting of conductive traces. Polyimide or flexible liquid photoimageable solder masks maintain adhesion during dynamic movement and enable accurate component placement. In WellPCB’s production, inspection systems confirm uniform solder mask coverage and registration, ensuring reliability for illuminated displays, instrument clusters, and backlight modules under cyclical mechanical strain.

Importance of Material Selection

Material selection shapes the flexibility, durability, and electrical integrity of flexible LED PCB flex circuits. High-performance materials in manufacturing processes enable these circuits to meet demanding electrical and thermal conditions across lighting, automotive, and wearable applications.

Impact on Flexibility and Durability

Material choices directly affect flexibility and durability in flexible LED PCB flex circuits. Polyimide films maintain bendability and resist mechanical fatigue, crucial for repeated flexing in applications like dynamic displays and folding consumer electronics. Copper foils combine with flexible adhesives, ensuring conductive traces don’t crack during flex cycles. Protective solder masks, as applied by WellPCB, reduce moisture intrusion, prevent corrosion, and extend the circuit’s service life. Adhesive systems certified by IPC-4101 further improve mechanical durability, supporting rugged designs in automotive dashboards and medical wearables.

Thermal and Electrical Performance

Thermal and electrical performance depends on precise material engineering. Polyimide substrates withstand temperatures up to 200°C, ensuring circuit stability near power LEDs or in heated environments. High-conductivity copper foils, adjustable in thickness by WellPCB production teams, optimize current-carrying capacity and minimize voltage drop. Low-loss adhesive systems can insulate while efficiently transmitting heat, preventing hotspots. Solder masks and selective surface finishes improve insulation and oxidation resistance, maintaining electrical performance under harsh conditions. WellPCB uses automated inspection to verify trace quality, securing reliable operation for demanding electronic assemblies.

Common Applications for Flexible LED PCB Flex Circuits

Flexible LED PCB flex circuits function in product segments that require reliable lighting in limited or irregular spaces. Electronics manufacturers use these circuits in automotive display backlights, automotive dashboard illumination, and interior accent lighting. Wearable device makers, including those creating fitness bands, medical monitoring patches, and smart clothing, embed flexible circuits to enable consistent light output and adaptability to curved surfaces.

Architectural lighting providers employ flexible LED PCB flex circuits to illuminate signage, showcase lighting, and under-cabinet installations, especially where routing through tight or contoured spaces is important. Consumer electronics brands integrate these circuits in foldable smartphones, edge-lit displays, and camera flash modules. Medical device companies use them in surgical lighting, portable diagnostic instruments, and flexible endoscope devices, benefiting from the circuits’ bend radius and stability in harsh environments. Industrial equipment makers rely on these circuits for machine vision systems and status indicator modules.

WellPCB in China supports these product sectors by providing precise manufacturing, automated optical inspection, and quick-turn prototyping for flexible LED PCB flex circuits, meeting technical requirements for tight bend radii, multilayer designs, and fine trace widths. This supports rapid product development and scalable production for global customers.

About WellPCB

WellPCB, located in Los Angeles, CA, is a leading provider of high-quality PCB manufacturing and assembly services.

Led by Hommer Zhao, Director of Sales and Marketing and Co-founder, WellPCB offers comprehensive solutions for PCB prototyping, assembly, and testing. The company is dedicated to delivering precision, reliability, and efficiency, ensuring that clients in industries such as electronics, telecommunications, automotive, and medical devices receive top-tier products and services.

Contact:

Hommer Zhao, Director of Sales and Marketing, Co-founder

Phone: (424) 842-2783

Email: [email protected]

Address: 3826 Medford St, Los Angeles, CA 90063, USA

Website: www.ourpcb.com

Frequently Asked Questions

What are flexible LED PCB flex circuits?

Flexible LED PCB flex circuits are electronic circuits built on thin, bendable materials. Unlike rigid PCBs, they can bend, twist, and fit into irregular or tight spaces, making them ideal for complex and compact device designs.

How do flexible LED PCBs differ from traditional rigid PCBs?

Flexible LED PCBs use materials like polyimide film, allowing them to bend and flex without breaking, unlike traditional rigid PCBs, which are stiff and can crack under stress. This flexibility enables more versatile design options.

What materials are used in flexible LED PCB flex circuits?

Key materials include polyimide films for the substrate, copper foils for conductive traces, flexible adhesives for bonding, and protective solder masks. These materials ensure durability, flexibility, and reliable performance in demanding environments.

What are the main benefits of using flexible LED PCB flex circuits?

Flexible LED PCB flex circuits offer enhanced flexibility, lightweight design, space savings, and increased reliability in dynamic or curved applications. They also improve performance in devices that require frequent movement or folding.

In which industries are flexible LED PCB flex circuits commonly used?

They are widely used in automotive lighting, wearable devices, consumer electronics, architectural lighting, medical equipment, and industrial machinery—anywhere compact, adaptable circuit designs are required.

How does material selection affect the performance of flexible LED PCB flex circuits?

Choosing high-quality materials directly impacts flexibility, durability, and electrical integrity. For example, polyimide films and well-selected copper foils allow the circuits to maintain performance even under mechanical and thermal stress.

Why is polyimide film preferred as the base material?

Polyimide film is preferred because it withstands high temperatures (up to 200°C), resists chemicals, and maintains flexibility and electrical performance, making it ideal for advanced electronic applications.

What role do adhesives and solder masks play in flexible LED PCB flex circuits?

Adhesives securely bond circuit layers while allowing flexibility and heat resistance. Solder masks protect against moisture and oxidation, which increases the circuit’s lifespan and reliability.

How does WellPCB ensure the reliability of flexible LED PCB flex circuits?

WellPCB uses precision etching, automated inspection, and rigorous quality control measures. Their advanced manufacturing processes ensure that every flex PCB meets high standards for performance and durability.

What are some common applications for flexible LED PCB flex circuits?

Common applications include automotive display backlighting, wearable health monitors, foldable smartphones, architectural signage, surgical lighting, flexible endoscopes, and machine vision systems in industrial equipment.